SG1950-4WJS

| Availability: | |

|---|---|

|

| |

SG1950-4WJS is widely used in the applications of whole sheets or large scaled parts precision grinding to certain thickness, precision surface sanding and polishing to certain surface roughness, and etc. Suitable materials includes titanium, molybdenum, aluminum, stainless steel, and carbon steel.

Applications:

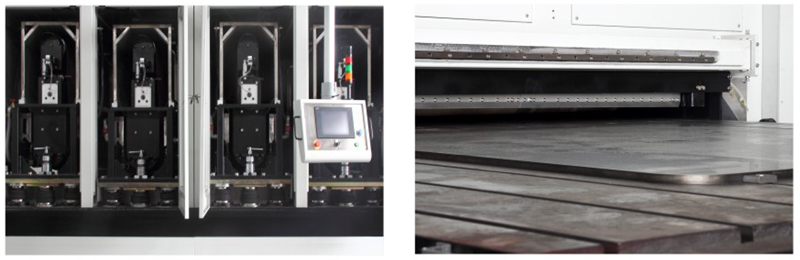

Reciprocating type working table: Work piece is clamped down and fixed on the working table. The whole working table moves back and forth repeatedly so the work piece can be processed by the work stations for multiple passes. The working table is driven by linear guide and ball screw drive to achieve high precision processing on the work piece. The working table feeding rate is adjustable between 2-9m/min.

Machine characteristic overview:

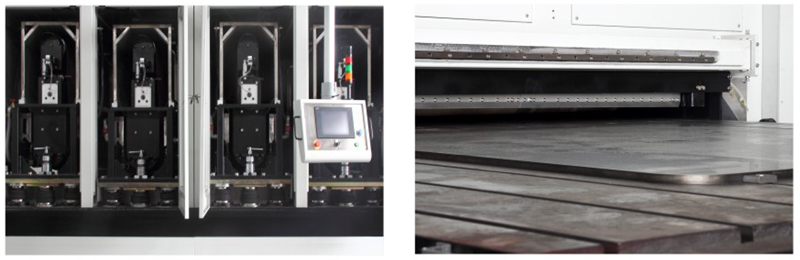

4 stations of gantry structured wide abrasive belt heads: each head has individual servo-motorized lifting to achieve high precision positioning to best accommodate the thickness of the work piece . Work station arrangement is modular, 1-4 wide abrasive belt heads is available.

Wet operation, utilizing recycled cutting fluid, to achieve optimal surface result. High pressure water spraying nozzles, and air knifes are equipped at the outfeed end of the working table to clean and remove if any metal dust from processing still adheres on the surface.

Automatic cutting fluid filtration unit.

Optional configuration |

Partial or full wet vacuum area on the working table |

Tecnical Datasheet | |||

| Maximum working width | 1000mm/1300mm/1600mm/1900mm | Minimum working length | 200mm |

Maximum working thickness | 100mm | Maximum working length | 3000mm |

Working table feeding rate | 2-9m/min | Working accuracy | ±0.03mm |

No. of work stations | 1-4 | Total power | 300kw |

Machine weight | 20000kgs | Machine dimension | 13500x4200x2300mm |

SG1950-4WJS is widely used in the applications of whole sheets or large scaled parts precision grinding to certain thickness, precision surface sanding and polishing to certain surface roughness, and etc. Suitable materials includes titanium, molybdenum, aluminum, stainless steel, and carbon steel.

Applications:

Reciprocating type working table: Work piece is clamped down and fixed on the working table. The whole working table moves back and forth repeatedly so the work piece can be processed by the work stations for multiple passes. The working table is driven by linear guide and ball screw drive to achieve high precision processing on the work piece. The working table feeding rate is adjustable between 2-9m/min.

Machine characteristic overview:

4 stations of gantry structured wide abrasive belt heads: each head has individual servo-motorized lifting to achieve high precision positioning to best accommodate the thickness of the work piece . Work station arrangement is modular, 1-4 wide abrasive belt heads is available.

Wet operation, utilizing recycled cutting fluid, to achieve optimal surface result. High pressure water spraying nozzles, and air knifes are equipped at the outfeed end of the working table to clean and remove if any metal dust from processing still adheres on the surface.

Automatic cutting fluid filtration unit.

Optional configuration |

Partial or full wet vacuum area on the working table |

Tecnical Datasheet | |||

| Maximum working width | 1000mm/1300mm/1600mm/1900mm | Minimum working length | 200mm |

Maximum working thickness | 100mm | Maximum working length | 3000mm |

Working table feeding rate | 2-9m/min | Working accuracy | ±0.03mm |

No. of work stations | 1-4 | Total power | 300kw |

Machine weight | 20000kgs | Machine dimension | 13500x4200x2300mm |